Trade Show Material Handling Tips

Material Handling costs, AKA drayage, is part of almost every US trade show and often confused with the process of shipping your booth. You may find these insider material handling tips useful.

Charging for Material Handling is one way the general contractor generates their revenues. These fees also cover the costs of materials and labor needed to move freight in and out of the venue and to store empty crates during the show.

Material Handling covers handling your shipments from off loading before the show to reloading after the show. This includes fork-lifting and the space required to store your empties during the show. At many venues, your freight and empty crates are loaded onto trailers due to onsite space limitations. Doing this however can add to higher Material Handling costs passed on to all exhibitors.

Material Handling is calculated based on the weight of freight, charging per hundred pounds. There are typically different rates for the different types of freight. For example, crated shipments are often less than pallet shipments. In general, the harder it is for the general contractor to unload and store your empty freight, the higher the cost will be.

Crates will generally cost less than shrink wrapped pallets. Rolls of carpet for example that aren’t banded to pallets will cost even more as they are considered to require special handling. Also, if your delivery truck is not dock height, you may be charged special handling fees. In short, Material Handing rates are set to incentivize exhibitors to pack and ship well.

Pro Tip: If you are thinking about sending your collateral or small boxes via FedEx or UPS, direct-to-show or advance warehouse you might want to think again. There will usually be special handling charges for these items. Boxes can get lost in the chaos of the show floor, so when possible, ship to your hotel or exhibit provider. This will help to ensure you have what you need for a successful show.

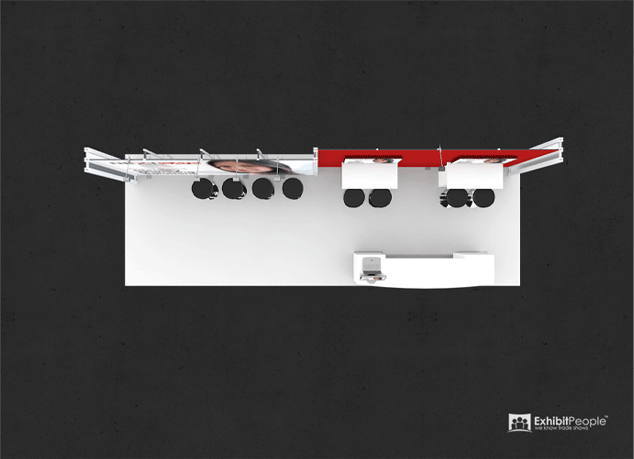

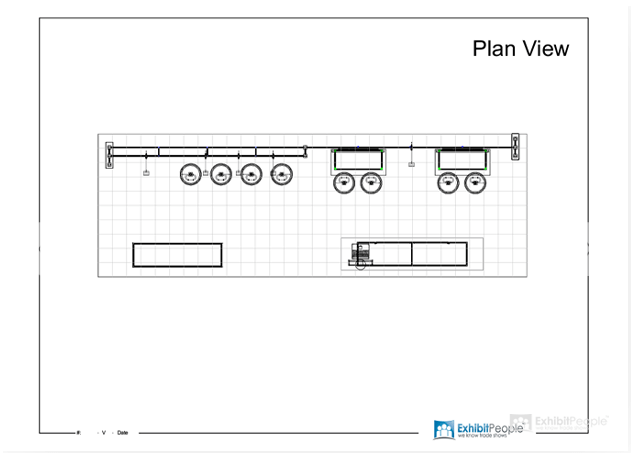

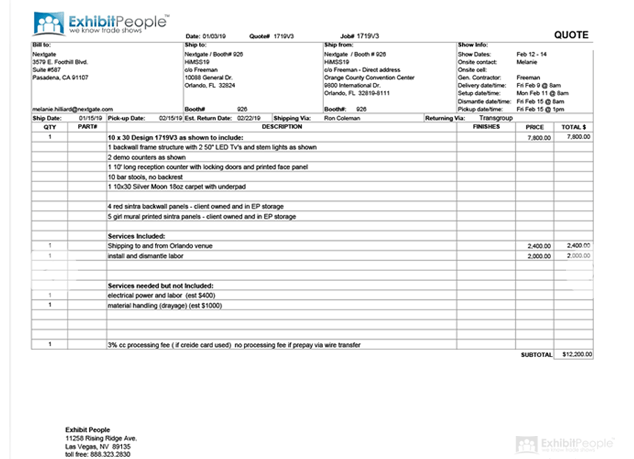

Rental Design Ideas Minimize Material Handling Costs

Some of the most important material handling tips for trade shows will seem intuitive. But we are surprised by how often these details are missed. Moreover; Our Project Managers know the ins and outs of Exhibitor Service Manuals and are always on the lookout for these 3 important pieces of information. This helps our clients pay the least amount of material handling possible.

First is complying with the move-in dates and times. Be aware of any targeted move-in/move-out times as well as advance warehouse dates. This will help you save paying additional fees for delivering freight off-target or outside of warehouse dates and hours. Target move-in refers to the date and time your driver must check in to collect the freight. Shows are fairly strict on this and the penalty is often a 30% surcharge for off-target freight. Shipping to advance warehouse may cost you a bit more, but it allows your freight to arrive ahead of the direct-to-show freight which means your installation team can get started sooner rather than later.

Second is properly packing your booth freight. Can all of your items fit in one or two crates? Does it make sense to ship odd-shaped items on top of your crate? Shipping companies charge what’s called dimensional weight for freight that is bulky. Your shipping company has a formula for determining if they will make more basing the fees on actual weight vs. dimensional weight. If you wrap one item to the top of the booth crate, keep in mind that is the same as a crate made tall enough for the additional height of that item. These are all things our team is tuned in to when packing and arranging for the shipment of your rental booth.

The third is reducing the weight of your shipment where possible. We focus on giving more booths for less money. We design and build our rental solutions using lighter materials such as aluminum frame structure, printed sintra, tension fabric. These factors will minimize your shipping and Material Handling costs. Overall, we’re looking at reducing the costs in using a rental booth, not just the cost of the booth itself.

Here’s what matters:

- Lighter booths have lower Material Handling Costs

- Shipping to Advance Warehouse is usually cheaper in the long run

- Select a quality shipper to insure your freight arrives without damage

- Plan to meet all important deadlines, delivery dates and driver check in dates/times